Umnyango Wokuphathwa Kwezisetshenziswa, iSinopec Yizheng Chemical Fiber Co., Ltd. 211900

Abstract: Leli phepha lihlaziya izimbangela ezingavamile zamayunithi amakhulu e-turbo expander, libeka phambili uchungechunge lwezinyathelo zokuxazulula izinkinga, futhi libamba amaphuzu engozi kanye nezinyathelo zokuvimbela zokusebenza.Ngokusetshenziswa kobuchwepheshe bokususa i-varnish, izingozi ezingase zifihlekile ziyaqedwa futhi nokuphepha kwangaphakathi kweyunithi kuyaqinisekiswa.

1. ukubuka konke

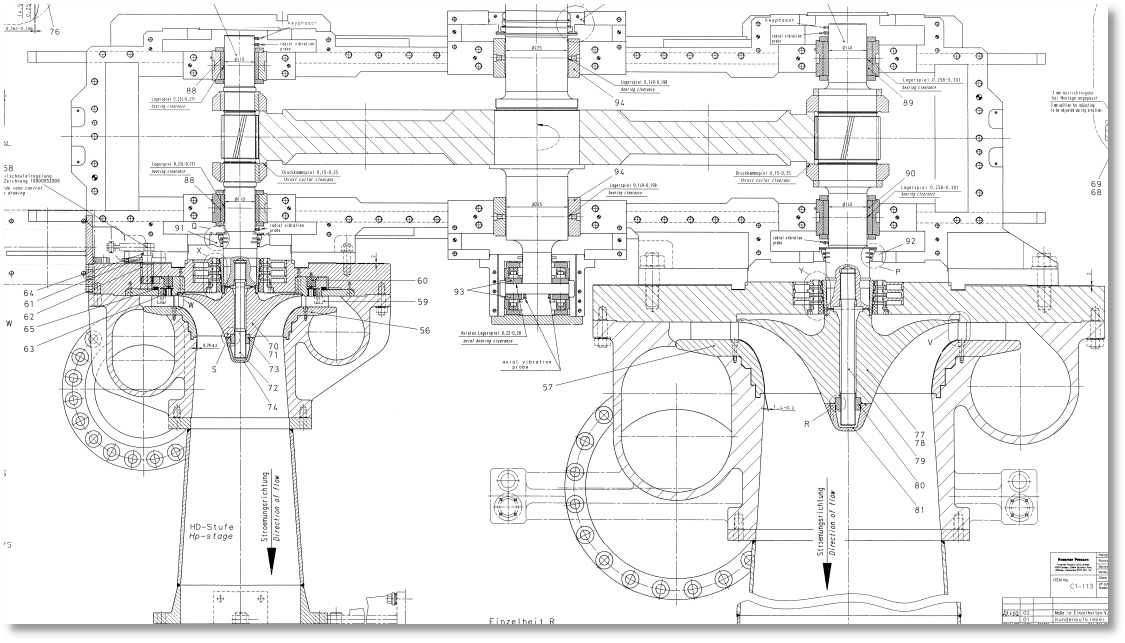

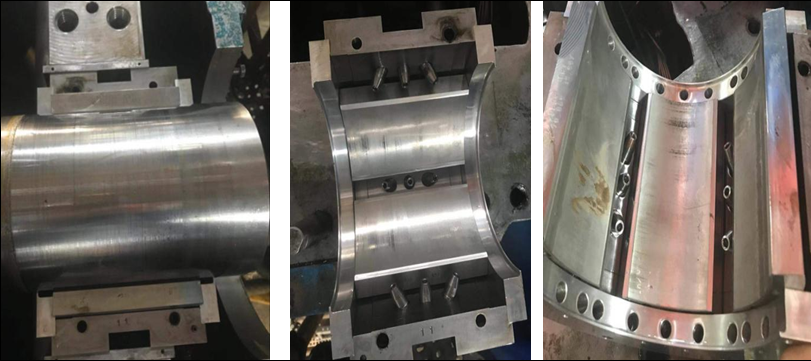

Iyunithi ye-compressor yomoya ye-60 t/a PTA plant ye-Yizheng Chemical Fiber Co., Ltd. ifakwe izinto zokusebenza ezivela eJalimane i-MAN Turbo.Iyunithi iyiyunithi yama-three-in-one, lapho iyunithi ye-compressor yomoya iyiyunithi ye-multi-shaft enezigaba ezinhlanu, i-condensing steam turbine isetshenziswa njengomshini oyinhloko wokushayela weyunithi ye-compressor yomoya, kanye ne-turbo expander esetshenziswa njengeyunithi ye-compressor yomoya.Umshini wokushayela osizayo.I-turbo expander yamukela ukuphakama kwezigaba ezimbili eziphezulu neziphansi, ngayinye inembobo yokudonsa kanye ne-exhaust port, futhi i-impeller ithatha i-impeller yezindlela ezintathu (bona Umfanekiso 1)

Umfanekiso 1 Ukubuka kwengxenye yeyunithi yokunweba (kwesokunxele: uhlangothi lokucindezela okukhulu; kwesokudla: uhlangothi lwengcindezi ephansi)

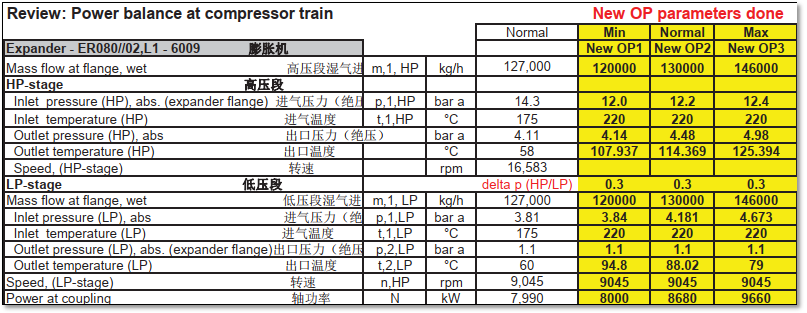

Imingcele yokusebenza eyinhloko ye-turbo expander imi kanje:

Ijubane eliphezulu le-high-pressure side liyi-16583 r/min, kanti ijubane le-low-pressure side liyi-9045 r/min;amandla alinganiselwe aphelele e-expander yi-7990 KW, futhi izinga lokugeleza liyi-12700-150450-kg/h;ingcindezi yokungena ingu-1.3Mpa, kanti ingcindezi yokukhipha ingu-0.003Mpa.Izinga lokushisa lokungenisa le-high-pressure side liyi-175 ° C, futhi izinga lokushisa lokukhipha liyi-80 ° C;izinga lokushisa lokungenisa le-low-pressure side liyi-175 ° C, futhi izinga lokushisa lokukhipha liyi-45 ° C;isethi yamaphedi atshekisayo asetshenziswa kuzo zombili iziphetho ze-high-pressure kanye ne-low-pressure side shaft shafts Ama-Bearings, ngalinye linamaphedi angu-5, ipayipi lokungena likawoyela lingangena kuwoyela ngezindlela ezimbili, futhi ibherethi ngalinye linembobo eyodwa yokufaka uwoyela, ngokusebenzisa Amaqembu ama-3 wemibhobho yomjovo kawoyela ayi-15, ububanzi bombobo wokungenisa uwoyela buyi-1.8mm, Kunezimbobo zokubuyisela uwoyela eziyi-9, futhi ngaphansi kwezimo ezijwayelekile, kusetshenziswa izimbobo ezi-5 namabhulokhi angu-4.Le yunithi ye-three-in-one isebenzisa indlela yokugcoba ngempoqo yokuphakelwa kukawoyela endaweni eyodwa kusuka esiteshini sikawoyela wokuthambisa.

2. Izinkinga nabasebenzi

Ngo-2018, ukuze kuhlangatshezwane nezidingo zokukhishwa kwe-VOC, iyunithi entsha ye-VOC yengezwe kudivayisi yokwelapha igesi yomsila we-oxidation reactor, futhi igesi yomsila ehlanjululwe yayisajovwe ku-expander.Ngenxa yokuthi usawoti we-bromide osegesini yokuqala yomsila ufakwa i-oxidized ezingeni lokushisa eliphezulu, kukhona ama-ion e-bromide.Ukuze uvimbele ama-ion e-bromide ukuthi angafinyeli futhi ahlukane lapho igesi yomsila inweba futhi isebenze ku-expander, izobangela ukugqwala komgodi ku-expander namathuluzi alandelayo.Ngakho-ke, kuyadingeka ukwandisa iyunithi yokwandisa.Izinga lokushisa lokungena kanye nezinga lokushisa lokukhipha umoya ohlangothini lomfutho ophezulu kanye nohlangothi lwengcindezi ephansi (bheka Ithebula 1).

Ithebula 1 Uhlu lwamazinga okushisa okusebenza endaweni yokungena nokuphuma kwe-expander ngaphambi nangemuva kokuguqulwa kwe-VOC

| CHA. | Ushintsho lwepharamitha | Uguquko lwangaphambili | Ngemva kwenguquko |

| 1 | Izinga lokushisa lomoya eliphakathi kwengcindezi ephezulu | 175 °C | 190 °C |

| 2 | Izinga lokushisa lokukhipha uhlangothi lokucindezela okuphezulu | 80 ℃ | 85 °C |

| 3 | Izinga lokushisa lomoya eliphansi lokucindezela okuphansi | 175 °C | 195 °C |

| 4 | Izinga lokushisa lokukhipha uhlangothi lokucindezela okuphansi | 45 °C | 65 °C |

Ngaphambi kokuguqulwa kwe-VOC, izinga lokushisa le-non-impeller side bearing ekupheleni kwengcindezi ephansi liye lazinza cishe ku-80 ° C (izinga lokushisa le-alamu lokuthwala lapha liyi-110 ° C, futhi izinga lokushisa eliphezulu liyi-120 ° C).Ngemuva kokuthi kuqalwe ukuguqulwa kwe-VOC ngoJanuwari 6, 2019, izinga lokushisa lohlangothi olungeyona i-impeller ekugcineni kokucindezela okuphansi kwe-expander lenyuka kancane, futhi izinga lokushisa eliphakeme kakhulu laliseduze nezinga lokushisa eliphakeme kakhulu elibikiwe elingu-120 ° C, kodwa imingcele yokudlidliza ayizange ishintshe kakhulu phakathi nalesi sikhathi (bheka Umfanekiso 2).

Umdwebo 2 wesilinganiso sokugeleza kwe-expander kanye nokudlidliza kwe-shaft eseceleni okungeyona i-drive kanye nezinga lokushisa

I-1 - umugqa wokugeleza wesi-2 - umugqa wokugcina ongashayeli 3 - umugqa wokudlidliza we-shaft non-drive

3. Ukuhlaziya imbangela kanye nendlela yokwelapha

Ngemva kokuhlola nokuhlaziya inkambiso yokuguquguquka kwezinga lokushisa lamabheringi enjini yomusi, nokuqeda izinkinga zokuboniswa kwethuluzi elisendaweni, ukushintshashintsha kwenqubo, ukudluliswa okumile kokugqoka kwebhulashi le-steam turbine, ukushintshashintsha kwesivinini semishini, kanye nekhwalithi yezingxenye, izizathu eziyinhloko zokubhekana nokuguquguquka kwezinga lokushisa. yilezi:

3.1 Izizathu zokwenyuka kwezinga lokushisa kwe-non-impeller side bear ekugcineni kwengcindezi ephansi yesinweshi

3.1.1 Ukuhlolwa kokuhlakazwa kutholwe ukuthi ibanga phakathi kwe-bearing ne-shaft kanye ne-meshing clearance yamazinyo egiya lalivamile.Ngaphandle kwe-varnish esolwayo endaweni ephethe uhlangothi olungeyona i-impeller ekugcineni kwengcindezi ephansi yesinweshi (bheka Umfanekiso 3), akukho okungavamile okutholakele kwamanye ama-bearings.

Umfanekiso 3 Isithombe esibonakalayo se-non-drive end bearing kanye ne-kinematic pair ye-expander

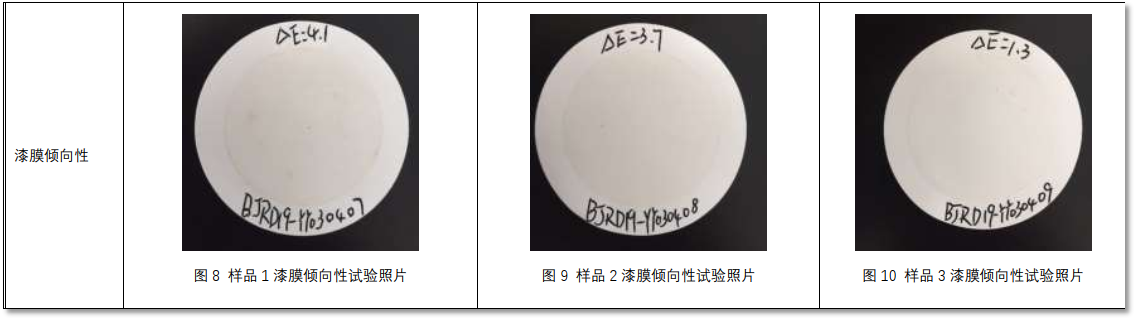

3.1.2 Njengoba uwoyela wokugcoba usushintshiwe isikhathi esingaphansi konyaka, izinga likawoyela seliphumelele ukuhlolwa ngaphambi kokushayela.Ukuze kuqedwe ukungabaza, inkampani yathumela amafutha okugcoba enkampanini yochwepheshe ukuze ayohlolwa futhi ahlaziywe.Inkampani yobungcweti iqinisekisa ukuthi okunamathiselwe endaweni ephethe i-varnish yokuqala, i-MPC (i-varnish propensity index) (bheka Umfanekiso 4)

Umfanekiso wesi-4 Umbiko wokuhlaziya ubuchwepheshe bokuqapha uwoyela okhishwe ubuchwepheshe obuchwepheshile bokuqapha uwoyela

3.1.3 Amafutha okugcoba asetshenziswa ku-expander i-Shell Turbo No. 46 turbine oil (amafutha amaminerali).Lapho amafutha amaminerali emazingeni okushisa aphezulu, amafutha okugcoba afakwe i-oxidized, futhi imikhiqizo ye-oxidation ibuthana ebusweni besihlahla esithwalayo ukuze yenze i-varnish.Amafutha okugcoba amaminerali ikakhulukazi akhiwe izinto ze-hydrocarbon, ezizinzile ngokuqhathaniswa nezinga lokushisa elilingana negumbi kanye nezinga lokushisa eliphansi.Kodwa-ke, uma amanye (ngisho nenani elincane kakhulu) lama-molecule e-hydrocarbon ethola ukusabela kwe-oxidation emazingeni okushisa aphezulu, amanye ama-molecule e-hydrocarbon nawo azobhekana nokusabela kweketango, okuwuphawu lokusabela kwe-hydrocarbon chain.

3.1.4 Ochwepheshe bezinto zokusebenza benze uphenyo mayelana nokwesekwa kwendikimba yesisetshenziswa, ingcindezi ebandayo yamapayipi okungenisa nokuphuma, ukutholwa kokuvuza kwesistimu kawoyela, kanye nobuqotho bokuhlola izinga lokushisa.Futhi kwashintsha isethi yamabheringi ekugcineni okungeyona i-drive ohlangothini oluphansi lwe-expander, kodwa ngemva kokushayela inyanga yonke, izinga lokushisa lisafinyelela ku-110 ℃, bese kuba nokuguquguquka okukhulu kokudlidliza kanye nezinga lokushisa.Ukulungiswa okuningana kwenziwa ukuze kusondele izimo ze-pre-retrofit, kodwa cishe ngaphandle kwanoma yimuphi umphumela (bheka Umfanekiso 5).

Umfanekiso 5 Ishadi Lethrendi lezinkomba ezihlobene kusukela ngo-February 13 kuya ku-March 29

umkhiqizi we-MAN Turbo, ngaphansi kwezimo zokusebenza zamanje ze-expander, uma umthamo womoya wokungenisa uzinzile ku-120 t/h, amandla okukhiphayo angama-8000kw, okucishe kufane namandla okukhipha umklamo wangempela we-7990kw ngaphansi kwezimo ezijwayelekile zokusebenza;Uma umthamo womoya ungu-1 30 t/h, amandla okukhipha angu-8680kw;uma umthamo womoya owuthathayo ungu-1 46 t/h, amandla okukhipha angu-9660kw.Njengoba umsebenzi owenziwe uhlangothi lwe-low-pressure akhawunti yezingxenye ezimbili kwezintathu ze-expander, uhlangothi oluphansi lwe-expander lungase lulayishwe kakhulu.Uma izinga lokushisa lidlula i-110 ° C, inani lokudlidliza lishintsha kakhulu, libonisa ukuthi i-varnish esanda kwakhiwa ebusweni be-shaft kanye nesihlahla esithwalayo siyaklwebha ngalesi sikhathi (bheka Umfanekiso 6).

Umfanekiso 6 Ithebula lebhalansi yamandla yeyunithi yokunweba

3.2Ukuhlaziywa Kwezindlela Zezinkinga Ezikhona

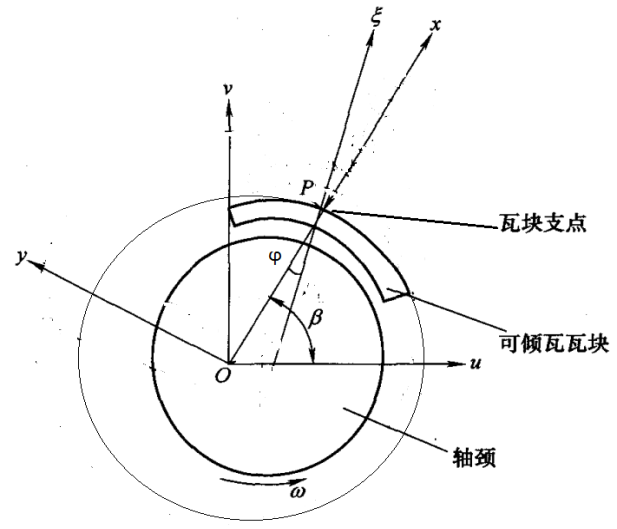

3.2.1 Njengoba kuboniswe kuMfanekiso 7, kungabonakala ukuthi i-engeli efakiwe phakathi kwesiqondiso sokudlidliza esincane se-fulcrum ye-tile block kanye nomugqa wokuxhumanisa ovundlile ohlelweni lokuxhumanisa ngu-β, i-angle yokushwibeka yebhulokhi yethayela ithi φ , kanye nesistimu yokuthwala i-tilting pad eyakhiwe ngamathayili angu-5, lapho i-tile Lapho i-pad ingaphansi kwengcindezi yefilimu kawoyela, njengoba i-fulcrum ye-pad ingewona umzimba oqinile ophelele, isikhundla se-fulcrum ye-pad ngemva kokuguqulwa kokucindezela kuyoba khiqiza ukugudluka okuncane eduze kwendlela yokulayisha kuqala yejiyomethri ngenxa yokuqina kwe-fulcrum, ngaleyo ndlela kuguqule imvume yokuthwala kanye nokuqina kwefilimu kawoyela [1] .

Fig.7 Ukudidiyela uhlelo lwephedi elilodwa lokuthwala iphedi elitshekisayo

3.2.2 Kungabonakala ku-Figure 1 ukuthi i-rotor iyisakhiwo se-cantilever, futhi i-impeller iyisici esiyinhloko somsebenzi.Njengoba uhlangothi lwe-impeller luwuhlangothi lokushayela, lapho igesi ikhula ukuze yenze umsebenzi, i-shaft ejikelezayo ohlangothini lwe-impeller isesimweni esihle kakhulu esihlahleni esithwalayo ngenxa yomphumela we-gas damping, futhi igebe likawoyela lihlala lijwayelekile.Enqubweni yokuhlanganisa kanye nokudlulisa i-torque phakathi kwamagiya amakhulu namancane, lokhu njenge-fulcrum, ukunyakaza kwamahhala kwe-radial ye-non-impeller side shaft kuzonqunyelwa ngaphansi kwezimo zokugcwala, futhi ingcindezi yayo yefilimu yokugcoba iphakeme kuneyezinye. ama-bearings, okwenza le ndawo igcotshwe Ukuqina kwefilimu kuyanda, izinga lokuvuselela ifilimu kawoyela liyancipha, futhi ukushisa okuphikisanayo kuyanda, okuholela ku-varnish.

3.2.3 I-varnish emafutheni ikhiqizwa ikakhulukazi ngezindlela ezintathu: i-oxidation kawoyela, i-oyela "i-micro-combustion", kanye nokukhishwa kwendawo okushisa kakhulu.I-varnish kufanele ibangelwe "i-micro-combustion" yamafutha.Umshini umi kanje: inani elithile lomoya (ngokuvamile elingaphansi kuka-8%) lizoncibilika emafutheni okugcoba.Uma umkhawulo wokuncibilika weqiwe, umoya ongena emafutheni uzoba khona emafutheni ngendlela yamabhamuza amisiwe.Ngemva kokungena ekuthwaleni, ukucindezela okuphezulu kubangela ukuthi lawa ma-bubbles acindezeleke ngokushesha kwe-adiabatic, futhi izinga lokushisa loketshezi likhuphuka ngokushesha ukuze libangele "i-micro-combustion" ye-adiabatic yamafutha, okuholela ekungangeni kwe-insolubles encane kakhulu.Lezi zinto ezingancibilikiyo ziyi-polar futhi zivame ukunamathela endaweni yensimbi ukuze zenze ama-varnish.Ukucindezela okukhulu, i-solubility ephansi yento engancibiliki, futhi kulula ukudlula futhi ixazulule ukwenza i-varnish.

3.2.4 Ngokwakhiwa kwe-varnish, ubukhulu befilimu yamafutha esimweni esingenaso samahhala sithathwe yi-varnish, futhi ngesikhathi esifanayo isivinini sokuvuselela ifilimu yamafutha siyancipha, futhi izinga lokushisa likhuphuka kancane kancane, okwandisa. ukungqubuzana phakathi kobuso besihlahla esithwalayo kanye ne-shaft, kanye ne-varnish ediphozithiwe ibangela ukushabalaliswa kahle kokushisa nokwenyuka kwezinga lokushisa likawoyela kuholela ekushiseni okuphezulu kwesihlahla.Ekugcineni, ijenali ihlikihla ivanisha, ebonakala ngokuguquguquka okunodlame ekudlidlizeni kwe-shaft.

3.2.5 Nakuba inani le-MPC lamafutha e-expander lingekho phezulu, uma kune-varnish ohlelweni lukawoyela wokugcoba, ukuncibilika kanye nokuna kwezinhlayiya zevarnish emafutheni kunqunyelwe ngenxa yekhono elilinganiselwe lamafutha okugcoba ukuncibilika. izinhlayiya ze-varnish.Iwuhlelo lwebhalansi oluguqukayo.Uma ifinyelela esimweni esigcwele, i-varnish izolenga ku-bearing noma i-bearing pad, okubangela ukushintshashintsha kwezinga lokushisa kwe-bearing pad, okuyingozi enkulu efihliwe ethinta ukusebenza okuphephile.Kodwa ngenxa yokuthi inamathela ku-bearing pad, ingenye yezizathu zokukhuphuka kwezinga lokushisa kwe-bearing pad.

4 Izinyathelo kanye Nezinyathelo Zokulwa

Ukususa ukuqoqwa kwe-varnish ekuthwaleni kungaqinisekisa ukuthi ukuthwala kweyunithi kugijima ekushiseni okulawulwayo.Ngokucwaninga nokuxhumana nabakhiqizi abaningi bemishini yokususa ivanisha, sikhethe i-Kunshan Winsonda, enomphumela omuhle wokusebenzisa nedumela lemakethe, ukukhiqiza i-WVD-II electrostatic adsorption + resin adsorption, okuwumshini wokuhlanganisa wokususa upende wokususa upende.ulwelwesi.

Izihlanzi zikawoyela eziwuchungechunge ze-WVD-II zihlanganisa ngempumelelo ubuchwepheshe bokuhlanza i-electrostatic adsorption kanye nobuchwepheshe bokushintshanisa i-ion, zixazulule i-varnish encibilikisiwe nge-resin adsorption, futhi zixazulule ukuvanisha okumanzi nge-electrostatic adsorption.Lobu buchwepheshe bunganciphisa okuqukethwe kwe-sludge ngesikhathi esifushane , Esikhathini esifushane sezinsuku ezimbalwa, isistimu yokugcoba yasekuqaleni equkethe inani elikhulu le-sludge / i-varnish ingabuyiselwa esimweni esihle kakhulu sokusebenza, futhi inkinga yokukhuphuka kancane izinga lokushisa le-thrust bear elibangelwa i-varnish lingaxazululwa.Ingakwazi ukususa ngempumelelo futhi ivimbele udaka lukawoyela oluncibilikayo nelungancibilikiyo olukhiqizwa ngesikhathi sokusebenza okuvamile kwe-steam turbine.

Izimiso zayo eziyinhloko imi kanje:

4.1 I-ion exchange resin ukususa ivanishi encibilikile

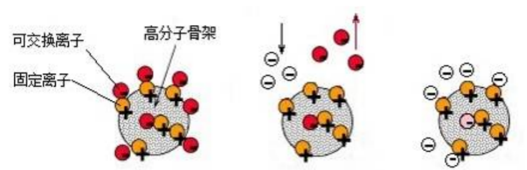

I-ion exchange resin yakhiwa ikakhulukazi izingxenye ezimbili: i-polymer skeleton kanye neqembu lokushintshisana nge-ion.Umgomo we-adsorption uboniswa kuMfanekiso 8,

Umfanekiso 8 Isimiso se-ion-interaction resin adsorption

Iqembu lokushintshisana lihlukaniswe laba ingxenye engaguquki kanye nengxenye enyakazayo.Ingxenye ehleliwe iboshwe ku-matrix ye-polymer futhi ayikwazi ukuhamba ngokukhululekile, futhi iba ion ehleliwe;ingxenye enyakazayo kanye nengxenye engaguquki kuhlanganiswe ngamabhondi e-ionic ukuze abe i-ion eshintshanayo.Ama-ion agxilile nama-ion eselula anezindleko eziphambene ngokulandelanayo.Esihlahleni esithwalayo, ingxenye yeselula ibola ibe ama-ion ahambayo ngokukhululekile, ashintshana neminye imikhiqizo yokuwohloka enenkokhiso efanayo, ukuze ahlangane nama-ion amisiwe futhi akhangiswa ngokuqinile kusisekelo sokushintshana.Eqenjini, isuswa ngamafutha, i-varnish encibilikisiwe ekhishwe i-ion exchange resin adsorption.

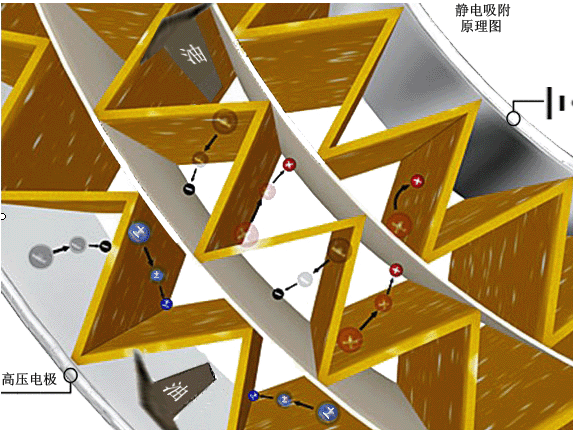

4.2 Ubuchwepheshe be-electrostatic adsorption ukususa ukuvanisha okumisiwe

Ubuchwepheshe be-electrostatic adsorption ikakhulukazi busebenzisa ijeneretha yamandla kagesi aphezulu ukuze kukhiqizwe inkambu ye-electrostatic enamandla kakhulu ukuze ihlukanise izinhlayiya ezingcolile kuwoyela ukuze zibonise ukushaja okuhle nokubi ngokulandelana.Izinhlayiya ezingathathi hlangothi zikhanywa futhi zihanjiswe yizinhlayiya ezikhokhisiwe, futhi ekugcineni zonke izinhlayiya ziyakhangiswa futhi zinamathele kumqoqi (bheka Umfanekiso 9).

Umfanekiso 8 Isimiso se-electrostatic adsorption technology

Ubuchwepheshe bokuhlanza uwoyela nge-electrostatic bungasusa konke ukungcola okungancibiliki, okuhlanganisa ukungcola kwezinhlayiya kanye nokuvenisha okulengisiwe okukhiqizwa ukuwohloka kukawoyela.Nokho, izakhi zokuhlunga zendabuko zingasusa kuphela izinhlayiya ezinkulu ngokunemba okuhambisanayo , futhi kunzima ukususa i-submicron i-varnish emisiwe yezinga .

Lolu hlelo lungakwazi ukuxazulula ngokuphelele i-varnish egayiwe futhi ifakwe ku-bearing pad, ngaleyo ndlela ixazulule ngokuphelele ithonya lokushisa kwe-bearing pad kanye nezinguquko zokudlidliza ezibangelwa i-varnish, ukuze iyunithi ikwazi ukugijima ngokuzinzile isikhathi eside .

5 Isiphetho

Iyunithi yokususa i-varnish ye-WSD WVD-II yasetshenziswa, phakathi neminyaka emibili yokubhekwa kokusebenza, izinga lokushisa elithwalayo belilokhu ligcinwe liba ngu-90 ° C, futhi iyunithi isaqhubeka nokusebenza okuvamile.Kutholwe ifilimu yokuvanisha (bheka uMdwebo 10).

Isithombe esibonakalayo sokuthwala i-disassembly ngemuva kokufaka ukususwa kwe-varnish

imishini

izinkomba:

[1] U-Liu Siyong, u-Xiao Zhonghui, u-Yan Zhiyong, no-Chen Zhujie.Ukulingisa kwezinombolo kanye nocwaningo lokuhlola ezicini eziguqukayo ze-pivot elastic and damping pad bearings [J].Ijenali yesi-Chinese yobunjiniyela bemishini, Okthoba 2014, 50(19):88.

Isikhathi sokuthumela: Dec-13-2022